Tools

Tools you should know about and how to used them. Creating groves for a machine screw. Drilling a hole accurately. Stripping a wire.

Most of these tools you can get at stores such as:

Clas Ohlson might be your first choice because they have a good selection and are usually easily accessible in shopping centers around Norway.

Drilling holes

When you drill a hole there are a lot of issues and challenges to consider:

- Is the hole straight?

- Do you want to put screws into it or rod or axel later?

- What to do when the hole is almost big enough but not quite.

- Are all my holes accurately aligned with each other?

- Are there any differences between making holes in wood or plastic.

To answer these questions I’d like to show some tools you should be aware of for working with holes.

Deburring Tool

Take off sharp edges or enlarge holes

When you drill a hole you can get a rough edge for the hole or the hold didn’t get quite large enough. Do deal with this you can use a deburring tool It can smoothen an edge or enlarge a hole slightly. Usually you buy these in kits because you need a different one depending on material you want to deburr. I could be refered to as a edge off tool rather than deburring tool.

When you drill a hole you can get a rough edge for the hole or the hold didn’t get quite large enough. Do deal with this you can use a deburring tool It can smoothen an edge or enlarge a hole slightly. Usually you buy these in kits because you need a different one depending on material you want to deburr. I could be refered to as a edge off tool rather than deburring tool.

Taper Tool

Make screw holes or turn a metal rod into a screw

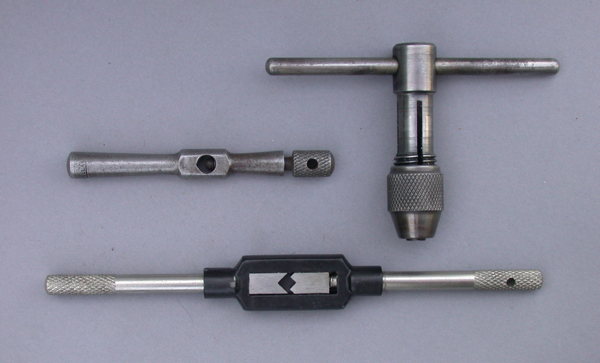

When you drill a hole it will be smooth inside so e.g. a machine screw won’t fasten in the hole. You need to cut a thread out of the side of the hole. This is called “tapping” and you do it by fastening a tap in a tap wrench (shown above):

You then screw the tap into the hole by hand in similar fashion to how you screw a screw. When you are done, you have to unscrew it carefully avoiding to ruin the thread you just cut. To turn a smooth metal rod into a screw you perform “threading” on it using a die wrench.